- PCB Assembly

- PCB Fab

- Resources

- Company

- Blog

Comprehensive Guide to Understanding Flexible Printed Circuit Boards for Modern Electronics

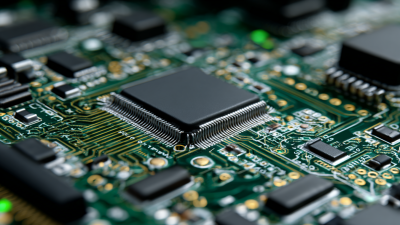

The demand for Flexible Printed Circuit Boards (FPCBs) has surged in recent years, driven by the rapid advancement of consumer electronics, automotive applications, and medical devices. According to a report by Research and Markets, the global flexible printed circuit board market is projected to reach $41.89 billion by 2026, growing at a CAGR of 10.58%. This growth underscores the importance of understanding the intricacies of FPCBs, which offer superior design flexibility, compactness, and multi-layered capabilities. As devices become more compact and technologically advanced, the role of FPCBs in enabling innovative solutions cannot be overstated. This guide aims to provide a comprehensive understanding of flexible printed circuit boards, exploring their types, manufacturing processes, applications, and the benefits they bring to modern electronics.

Key Differences Between Flexible and Rigid Circuit Boards

Flexible printed circuit boards (FPCBs) and rigid circuit boards (PCBs) are essential components in modern electronics, each offering unique advantages tailored to various applications. The most significant difference lies in their material and structural design. FPCBs are made from flexible materials like polyimide, allowing them to bend and fit into compact spaces. This flexibility results in lighter and more versatile designs, ideal for devices like smartphones and wearables. On the other hand, rigid PCBs are constructed from solid materials like FR-4, providing stability and durability but limiting application to flat, predictable designs.

When designing electronics, consider the intended application. If you're focusing on compact, lightweight devices, opt for FPCBs. They offer the luxury of flexibility while accommodating complex circuitry. **Tip:** Always ensure the bend radius meets manufacturer specifications to prevent damage during assembly or use. Alternatively, if your project requires robust support and higher heat resistance, rigid PCBs may be the better choice. **Tip:** Evaluate the PCB thickness and layer count to suit both performance and manufacturing requirements efficiently.

Choosing between FPCBs and rigid PCBs can deeply impact your project's success. **Tip:** Collaborate with your PCB supplier early in the design stage to explore the best material options, ensuring you leverage the full potential of each circuit type for your electronic applications.

Comprehensive Guide to Understanding Flexible Printed Circuit Boards for Modern Electronics - Key Differences Between Flexible and Rigid Circuit Boards

| Feature | Flexible Circuit Boards | Rigid Circuit Boards |

|---|---|---|

| Material | Polyimide or PET film | FR4 epoxy resin |

| Flexibility | Highly flexible, can bend and twist | Rigid, fixed shape |

| Weight | Lightweight | Heavier due to rigidity |

| Cost | Generally higher for production | Lower manufacturing cost |

| Applications | Wearable devices, medical equipment | Consumer electronics, automotive |

| Manufacturing Complexity | More complex, requires specialized techniques | Less complex, traditional methods |

| Thermal Management | Limited heat dissipation | Better heat management |

Advantages of Flexible Printed Circuit Boards in Modern Electronics

Flexible Printed Circuit Boards (FPCBs) have emerged as a pivotal component in the realm of modern electronics. Their inherent advantages over traditional rigid boards make them particularly appealing for various applications. One of the primary benefits of FPCBs is their ability to adapt to space constraints without compromising functionality. Their lightweight and slim profile allow for design flexibility, enabling engineers to create more compact and sophisticated devices.

Another significant advantage of flexible circuits is their resilience and durability. Unlike rigid boards, FPCBs can withstand bending and folding, which increases their longevity in dynamic environments. This feature is especially valuable in wearable technology and mobile devices, where space is at a premium, and components are subjected to constant movement. Additionally, the manufacturing process for FPCBs typically results in lower costs and reduced waste, making them an environmentally friendly option in electronic design. As industries continue to innovate, the role of flexible printed circuit boards will undoubtedly expand, enhancing the functionality and performance of modern electronics.

Applications of Flexible Circuit Boards Across Various Industries

Flexible printed circuit boards (FPCBs) have found their way into a multitude of modern applications across various industries, owing to their unique advantages such as lightweight design, space efficiency, and dynamic flexibility. These attributes make them indispensable in sectors like consumer electronics, automotive, and medical technology. For instance, in the consumer electronics market, the rising adoption of smart devices, particularly smartphones, is driving the demand for FPCBs. As the global market for printed circuit boards is projected to grow significantly, exceeding $26 billion by 2029, the role of FPCBs in these devices is becoming increasingly pivotal.

Moreover, the healthcare industry is experiencing a surge in the integration of flexible circuit boards into bio-microsystems and diagnostic tools, enhancing their functionality and efficiency. The latest advances in Lab-on-PCB technology highlight how FPCBs support innovative healthcare solutions, enabling the development of compact and sophisticated medical devices. As businesses look to adopt sustainable practices, the exploration of biodegradable substrates for FPCBs is also gaining momentum, promising a more environmentally friendly approach to electronic manufacturing. With continuous innovations and a steady growth forecast, flexible printed circuit boards are truly at the forefront of modern electronics across diverse industries.

Cost-Benefit Analysis: Flexible vs. Rigid Circuit Boards

When considering the cost-benefit analysis of flexible printed circuit boards (FPCBs) versus rigid circuit boards, it's essential to recognize the significant advantages that FPCBs provide in modern electronics. According to a report by MarketsandMarkets, the flexible printed circuit board market is projected to reach $30.3 billion by 2026, growing due to their lightweight design and superior adaptability. This dynamic flexibility allows manufacturers to create more compact and intricate electronic systems, supporting trends toward miniaturization in consumer electronics.

Moreover, while initial costs for FPCBs may be higher, the long-term benefits often outweigh these expenses. A study published in the Journal of Electronic Materials highlights that flexible circuits can reduce assembly time by up to 40% compared to traditional rigid boards. This increase in efficiency not only translates to faster production times but also diminishes the likelihood of defects during manufacturing, ultimately leading to lower overall costs. With the growing adoption of FPCBs across industries ranging from telecommunications to automotive, the economic benefits become increasingly apparent as companies invest in technology that enhances performance and reliability.

Cost-Benefit Analysis: Flexible vs. Rigid Circuit Boards

Design Considerations When Choosing Between PCB Types

When designing modern electronics, one of the crucial considerations is the choice between different types of printed circuit boards (PCBs). Among these, flexible printed circuit boards (FPCBs) have become increasingly popular due to their versatility and space-saving attributes. Unlike traditional rigid PCBs, FPCBs can bend and conform to the needs of compact gadget designs, making them an ideal choice for applications in smartphones, wearables, and automotive technology. As the automotive PCB market is projected to grow from $9.15 billion in 2023 to $15.1 billion by 2032, understanding the advantages of FPCBs becomes essential for engineers and product developers.

When selecting the appropriate PCB type, several design considerations come into play. Factors such as the expected mechanical stress, thermal management, and weight restrictions need to be carefully evaluated. FPCBs often offer significant benefits in terms of reduced weight and improved reliability in dynamic environments, which are especially valuable in the automotive sector. By aligning the PCB choice with the functionality and form factor of the end product, designers can maximize performance while minimizing size and weight—vital considerations in the growing demand for efficient, compact electronics.

Related Posts

-

Global Best Flexible PCB Boards Made in China Your Trustworthy Quality Choice

-

Ultimate Guide to Choosing the Best Flexible Circuit Board for Your Project

-

Top Strategies for Maximizing Performance with Flex Circuit Boards in Modern Electronics

-

A Comprehensive Comparison of Top PCB Circuit Board Manufacturers

-

Discover Pcb Circuit Board Innovations at the Record Breaking 137th Canton Fair in Guangzhou

-

Understanding Global Industry Standards for Best PCB Printed Circuit Boards in Modern Manufacturing

Phone

WhatsApp

WhatsAppEmail

Offer Electronics Manufacturing All-in-One

PCBONLINE® is a registered trademark or service mark of pcb online limited or its affiliates.

Copyright © 2001-2024 Pcb Online Limited. All rights reserved