- PCB Assembly

- PCB Fab

- Resources

- Company

- Blog

Top Strategies for Sourcing Quality Electronic Circuit Boards Globally

In today's fast-paced technological landscape, the demand for high-quality electronic circuit boards (ECBs) continues to escalate as industries from consumer electronics to automotive increasingly rely on sophisticated electronic systems. According to a report by MarketsandMarkets, the global electronic circuit board market is projected to grow from $60.2 billion in 2023 to $81.5 billion by 2028, reflecting a CAGR of 6.2%. This rapid growth highlights the critical importance of sourcing quality ECBs to ensure both performance and reliability in end products. However, navigating the complex global supply chain poses challenges such as varying quality standards, lead times, and sourcing strategies. In this blog, we will explore the top strategies for sourcing quality electronic circuit boards globally, providing insights that are essential for manufacturers seeking to enhance their procurement processes and maintain competitive advantage in an ever-evolving market.

Understanding the Importance of Quality Electronic Circuit Boards in Modern Manufacturing

In today’s manufacturing landscape, quality electronic circuit boards (ECBs) play a pivotal role in ensuring that devices function reliably and efficiently. As the backbone of electronic devices, these boards must meet stringent performance standards to support everything from consumer electronics to intricate industrial machinery. With the global market expanding, understanding how to source high-quality ECBs is crucial for manufacturers aiming to maintain their competitive edge.

Tip: Conduct Thorough Supplier Audits

Before finalizing a supplier, conducting detailed audits can reveal essential insights into their production processes and quality control measures. Assessing their certifications, such as ISO standards, ensures that they adhere to best practices in manufacturing. It’s also beneficial to request samples to evaluate the quality firsthand.

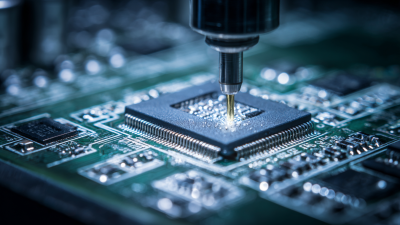

Tip: Leverage Technology for Quality Assurance

Utilizing advanced technologies such as automated inspection systems can significantly enhance quality assurance. Implementing these systems allows real-time monitoring of production, catching defects early in the process. This proactive approach not only saves costs associated with rework but also establishes a reputation for reliability in the products you deliver.

By prioritizing quality in every phase of the sourcing process, manufacturers can foster stronger relationships with suppliers and secure top-tier electronic circuit boards essential for modern production demands.

Key Factors to Consider When Sourcing Circuit Boards Internationally

When sourcing electronic circuit boards (PCBs) internationally, several key factors deserve careful consideration to ensure quality and sustainability in your supply chain. The growing scrutiny of sourcing practices highlights the importance of selecting suppliers who are not only compliant with international standards but also demonstrate a commitment to environmental stewardship. Recent reports indicate that the global PCB market is expected to reach US$ 107.6 billion by 2030, with an annual growth rate exceeding 4.1%. This burgeoning market underscores the necessity for businesses to stay informed about supply chain dynamics.

Tip 1: Assess suppliers for their compliance with environmental regulations and their efforts in recyclability. As the industry shifts towards a circular economy, understanding suppliers' capabilities related to recycling and resource recovery can help ensure ongoing sustainability.

Tip 2: Consider geopolitical factors that may impact sourcing decisions. Recent analyses have illustrated how global events influence supply chains, particularly in critical areas such as semiconductor production and PCB manufacturing. Evaluating a supplier's geographic location and political climate can help mitigate risks associated with sourcing.

Engaging with suppliers who prioritize innovation and technological advancements, such as deep learning frameworks for defect classification, can enhance the quality and reliability of PCBs procured internationally, ensuring partners stay competitive in this growing market.

Top Strategies for Sourcing Quality Electronic Circuit Boards Globally

This chart illustrates the key factors to consider when sourcing electronic circuit boards globally, rated on a scale from 1 to 10 based on their importance. Supplier quality and regulatory compliance are the most critical factors, while communication and technical expertise are also significant.

Evaluating Potential Suppliers: Criteria for Selecting Quality Circuit Board Manufacturers

When sourcing quality electronic circuit boards globally, evaluating potential suppliers is a critical step in ensuring

product excellence. One of the most important criteria to consider is the manufacturer’s industry certifications.

Look for suppliers with certifications such as ISO 9001 or

IPC standards, as these reflect a commitment to high-quality

production practices and continuous improvement.

Another key factor to consider is the supplier's experience and reputation in the market. Research their history

in the industry, and reach out to previous clients if possible. This can provide insights into their reliability

and the quality of their products. Additionally, review case studies or testimonials to better understand their

capability in delivering complex requirements.

Tip: Always request samples before making a large order to

evaluate the quality directly.

Lastly, assess the supplier's production capabilities and equipment. A manufacturer with modern machinery and

advanced technology is better positioned to produce high-quality circuit boards. Ensure that they can meet your

specific technical requirements and have a robust quality control process in place.

Tip: Schedule a factory visit if feasible, as this can give

you a clearer picture of their operations and quality assurance measures.

Navigating Supply Chain Challenges in Global Circuit Board Procurement

Navigating supply chain challenges in global circuit board procurement has become increasingly critical as the automotive PCB market is projected to grow significantly over the coming years. With an expected market size increase from $9.15 billion in 2023 to $15.1 billion by 2032, achieving efficient sourcing of electronic circuit boards requires strategic initiatives that mitigate supply chain disruptions. Particularly in the Asia-Pacific region, where tourism and other sectors are rebounding post-pandemic, businesses find themselves grappling with operational strains due to ongoing supply chain issues.

To effectively source high-quality circuit boards, companies must adopt a proactive approach in managing their supply chains. This includes establishing robust relationships with suppliers, embracing digital transformation for better logistics management, and remaining agile to market fluctuations. Companies that can navigate these complexities will not only enhance their competitiveness but also ensure a sustainable procurement process that meets the rising demand for quality electronic components in an increasingly interconnected global marketplace.

Best Practices for Ensuring Quality Control in Imported Circuit Boards

When sourcing electronic circuit boards globally, ensuring quality control during the import process is crucial. One of the best practices involves establishing clear specifications before placing orders. This means collaborating closely with manufacturers to define materials, dimensions, and performance standards. By detailing these requirements, businesses can minimize discrepancies and align the products received with their operational needs.

Another key strategy is to conduct regular audits and inspections of the manufacturing facilities. Engaging third-party quality assurance services can help in evaluating production processes and ensuring compliance with international standards. Pre-shipment inspections are also vital; they verify that the circuit boards meet the agreed-upon specifications before leaving the supplier's facility. Additionally, developing strong relationships with reputable manufacturers can further enhance quality. Trust and open communication facilitate proactive problem-solving, ultimately leading to consistent quality in imported circuit boards.

Top Strategies for Sourcing Quality Electronic Circuit Boards Globally

| Strategy | Description | Quality Control Measure | Frequency of Evaluation |

|---|---|---|---|

| Supplier Audits | Conduct regular on-site audits of suppliers to assess their manufacturing processes. | ISO 9001 Certification Check | Annually |

| Prototyping | Develop prototypes to ensure the design meets specifications before mass production. | Functional Testing | Before Production |

| Material Inspection | Inspect raw materials for compliance with standards before production starts. | Material Certification | Before Production |

| Post-Production Testing | Conduct tests on the final products to ensure they meet required specifications. | Electrical Performance Testing | Each Batch |

| Supplier Collaboration | Work closely with suppliers to align on quality expectations and continuous improvement. | Joint Quality Reviews | Quarterly |

Related Posts

-

Top 10 Circuit Board Fabrication Manufacturers from China at the 137th Canton Fair

-

Understanding Industry Production Standards for Best Circuit Board Assembly Techniques

-

Solutions for Exceptional Circuit Board Fabrication Techniques

-

Discover Pcb Circuit Board Innovations at the Record Breaking 137th Canton Fair in Guangzhou

-

Mastering the Art of Best Printed Circuit Board Assembly Step by Step Guide

-

Solutions for Achieving the Best Printed Circuit Board Assembly Quality in High-Demand Industries

Phone

WhatsApp

WhatsAppEmail

Offer Electronics Manufacturing All-in-One

PCBONLINE® is a registered trademark or service mark of pcb online limited or its affiliates.

Copyright © 2001-2024 Pcb Online Limited. All rights reserved