- PCB Assembly

- PCB Fab

- Resources

- Company

- Blog

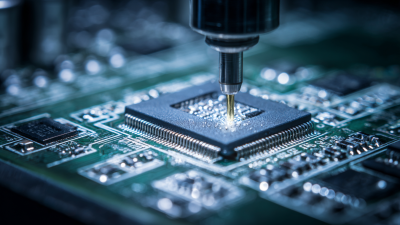

Revolutionizing Electronics: The Future of High-Performance Circuit Boards

The landscape of electronics is undergoing a transformative shift, driven by the increasing demand for high-performance circuit boards capable of meeting the complexities of modern technology. According to a recent report by MarketsandMarkets, the global printed circuit board (PCB) market is projected to reach USD 104.12 billion by 2026, growing at a CAGR of 4.4% from 2021 to 2026. This growth is fueled by advancements in IoT, automotive, and consumer electronics industries, which require more sophisticated and efficient circuit board designs.

As the future unfolds, innovative materials, such as flexible and hybrid circuits, are paving the way for enhanced performance, miniaturization, and sustainability, highlighting the critical role that circuit boards will play in the next generation of electronic devices. This article will explore the methodologies and technologies that are revolutionizing the design and production of circuit boards, ultimately enhancing their functionality and performance in an increasingly digital world.

Emerging Material Innovations in High-Performance Circuit Boards

The electronics industry is on the brink of a profound transformation, driven by innovative materials that are redefining the capabilities of high-performance circuit boards. Traditional materials, while effective, often come with limitations in thermal management and signal integrity. Emerging materials such as flexible substrates, high-frequency laminates, and advanced composites are enabling manufacturers to push the boundaries of performance. These innovations not only enhance the efficiency of circuits but also reduce weight and improve the durability of electronic devices, making them ideal for applications in telecommunications, automotive, and aerospace sectors.

Furthermore, the introduction of nanomaterials and conductive inks is revolutionizing circuit board design. By utilizing materials at the nanoscale, manufacturers can achieve superior electrical performance, leading to faster and more reliable devices. For instance, carbon nanotubes and graphene are being explored for their exceptional conductive properties, potentially replacing traditional copper traces. This shift not only fosters improved functionality but also opens doors for eco-friendly manufacturing processes. As these material innovations gain traction, the future of high-performance circuit boards looks promising, paving the way for smarter and more powerful electronic systems.

Enhancing Thermal Management for Advanced Electronics

The evolution of high-performance circuit boards is intrinsically linked to advancements in thermal management technologies. As electronics continue to shrink in size while increasing in performance, efficient heat dissipation has become critical to ensure reliability and longevity. According to a report by ResearchAndMarkets, the global thermal management market is projected to reach over $20 billion by 2026, driven by the demand for better thermal solutions in sectors such as automotive and consumer electronics. This growing market highlights the need for innovative materials and designs that can effectively manage heat in compact circuitry.

One promising approach to enhance thermal management is the integration of advanced materials like graphene and ceramic composites into circuit board manufacturing. These materials not only boast higher thermal conductivity compared to traditional substrates but also offer greater durability and performance under extreme conditions. In fact, a study published in the Journal of Materials Science indicates that incorporating graphene can improve thermal conductivity by up to 500%, a game-changer for high-performance applications.

**Tips:** When designing circuit boards, consider incorporating thermal vias and pads to facilitate heat transfer. Additionally, utilizing thermal interface materials can help bridge gaps between components and enhance overall heat dissipation. Keep in mind that regular thermal analysis during the design phase can preemptively identify potential hotspots, ensuring a more efficient final product.

Miniaturization Trends: Compact Designs for Modern Applications

The trend of miniaturization in electronics is driving the design of

compact circuit boards that meet the demands of

modern applications. As devices become smaller and more powerful, engineers are tasked with creating

high-performance circuit boards that maximize space while maintaining functionality. This shift

not only enhances portability but also allows for more intricate designs, enabling a wider range of features

in smaller packages.

Advancements in materials and manufacturing techniques play a crucial role in this miniaturization trend.

The use of innovative substrates and components helps

to reduce the size of circuit boards without compromising performance. Techniques such as surface mount

technology (SMT) and advanced packaging solutions allow for the integration of multiple functions into a

single board, streamlining the design process. Consequently, we are witnessing a new era of electronics where

compact designs are not just a preference but a necessity to keep pace

with consumer demands for lightweight, efficient devices.

Integration of AI in Circuit Board Design and Manufacturing

The integration of artificial intelligence (AI) in circuit board design and manufacturing is poised to reshape the electronics landscape dramatically. AI algorithms can analyze vast datasets, optimizing design parameters and enhancing performance while significantly reducing the time required for prototyping and testing. By leveraging machine learning techniques, engineers can predict potential flaws in circuit designs before they even move to production, allowing for a more efficient and cost-effective manufacturing process.

Moreover, AI can facilitate real-time monitoring of assembly lines, ensuring precision and quality control throughout the manufacturing phase. Intelligent systems can identify discrepancies and automatically adjust processes to maintain optimal production standards. This dynamic feedback loop not only enhances productivity but also enables manufacturers to adapt quickly to market demands or changes in technology. As AI continues to evolve, its synergy with circuit board design and manufacturing will undoubtedly lead to faster innovation cycles and the creation of increasingly sophisticated electronic devices.

Revolutionizing Electronics: The Future of High-Performance Circuit Boards - Integration of AI in Circuit Board Design and Manufacturing

| Parameter | Value | Impact of AI |

|---|---|---|

| Material Type | FR-4, Rogers, Polyimide | AI optimizes the selection of materials based on performance metrics. |

| Layer Count | 1 to 12 layers | AI assists in determining the minimum layer count required for efficiency. |

| Manufacturing Time | 3-5 days | AI algorithms predict delays and improve scheduling. |

| Defect Rate | < 2% | AI monitors processes in real-time to reduce defect rates. |

| Cost per Board | $25 - $100 | AI analyzes cost factors to optimize pricing models. |

| Design Software | Altium Designer, Cadence | AI tools integrated into design software enhance design accuracy. |

Sustainability in Electronics: Eco-Friendly Circuit Board Solutions

The electronics industry stands at a pivotal moment where sustainability is becoming a guiding principle in the development of circuit boards. Eco-friendly circuit board solutions are not only crucial in reducing environmental impact but also present new opportunities for innovation and efficiency. Many manufacturers are now exploring biodegradable materials and non-toxic substances in circuit board production, which can significantly decrease electronic waste and toxic emissions. By adopting these practices, companies can contribute to a greener future while meeting the growing consumer demand for sustainable products.

**Tip:** When selecting circuit board suppliers, look for those that prioritize sustainable practices. Check if they adhere to regulations regarding material usage and waste management, as this can be a clear indicator of their commitment to eco-friendliness.

Furthermore, integrating sustainable practices also involves rethinking the design and production processes. Utilizing modular designs can lead to easier repairs and upgrades, extending the lifespan of electronic products. This approach minimizes waste and promotes a circular economy within the electronics sector. When products can be easily repaired or upgraded, we not only reduce the accumulation of discarded devices but also save resources.

**Tip:** Consider investing in products that allow for upgrades or repairs. This not only supports sustainability but can also enhance the longevity of your electronics, leading to long-term cost savings.

Revolutionizing Electronics: The Future of High-Performance Circuit Boards

This chart illustrates the growing trend of sustainable materials used in circuit board manufacturing over the past few years. The data highlights the shift towards eco-friendly solutions in electronics.

Related Posts

-

Top 10 Circuit Board Fabrication Manufacturers from China at the 137th Canton Fair

-

Understanding Industry Production Standards for Best Circuit Board Assembly Techniques

-

Solutions for Exceptional Circuit Board Fabrication Techniques

-

Top Strategies for Sourcing Quality Electronic Circuit Boards Globally

-

How to Choose the Right Partner for Your Circuit Board Manufacturing Needs

-

What is the Importance of Quality Control in Circuit Board Manufacturing

Phone

WhatsApp

WhatsAppEmail

Offer Electronics Manufacturing All-in-One

PCBONLINE® is a registered trademark or service mark of pcb online limited or its affiliates.

Copyright © 2001-2024 Pcb Online Limited. All rights reserved