- PCB Assembly

- PCB Fab

- Resources

- Company

- Blog

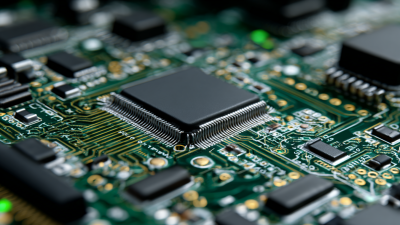

What is the Importance of Quality Control in Circuit Board Manufacturing

In the realm of Circuit Board Manufacturing, quality control plays a pivotal role in ensuring the reliability and performance of electronic devices. According to industry statistics, nearly 70% of manufacturing errors in circuit boards stem from inadequate quality assurance processes, leading to significant financial losses estimated at $2.5 billion annually for manufacturers. Moreover, a report from the IPC (Association Connecting Electronics Industries) indicates that the demand for defect-free circuit boards has surged, with projections showing a 4.5% growth rate in the global circuit board market. As the complexity of designs increases and the market continues to evolve, implementing stringent quality control measures becomes essential not only for meeting regulatory standards but also for enhancing customer satisfaction and maintaining a competitive edge. This blog delves into the critical importance of quality control in circuit board manufacturing, highlighting best practices and innovative strategies to mitigate risks and elevate product quality.

Understanding Quality Control in Circuit Board Manufacturing

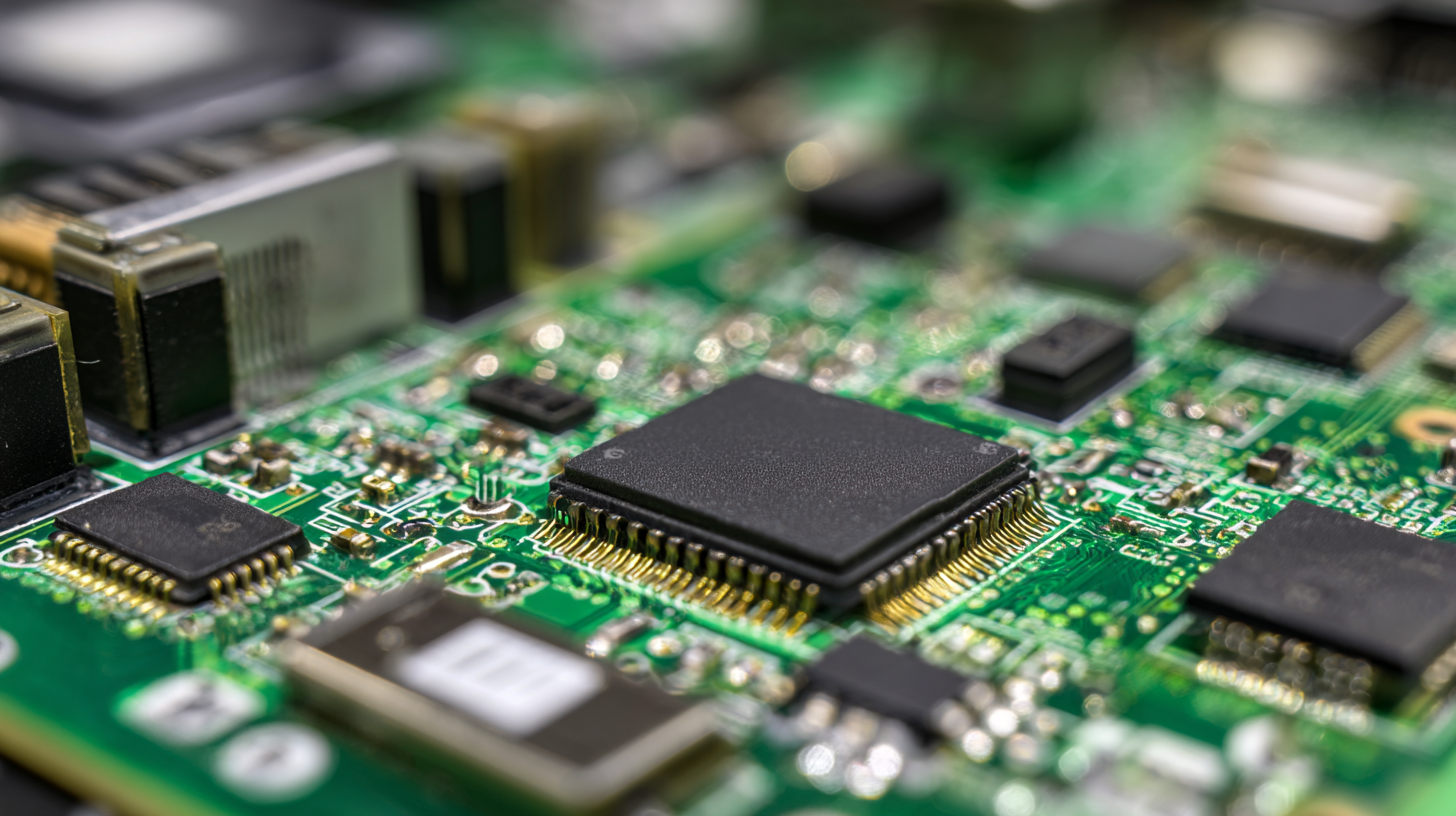

Quality control in circuit board manufacturing is essential for ensuring the reliability and performance of electronic devices. The intricate nature of circuit boards, which serve as the backbone of most electronic products, highlights the need for rigorous quality control measures at every stage of the manufacturing process. From the selection of raw materials to the final assembly, each step must undergo thorough inspection to identify and rectify potential defects. This meticulous attention to quality helps prevent costly failures in end products and enhances overall customer satisfaction.

Quality control in circuit board manufacturing is essential for ensuring the reliability and performance of electronic devices. The intricate nature of circuit boards, which serve as the backbone of most electronic products, highlights the need for rigorous quality control measures at every stage of the manufacturing process. From the selection of raw materials to the final assembly, each step must undergo thorough inspection to identify and rectify potential defects. This meticulous attention to quality helps prevent costly failures in end products and enhances overall customer satisfaction.

Understanding quality control practices in this industry involves familiarizing oneself with various testing methodologies, such as Automated Optical Inspection (AOI) and X-ray inspection. These techniques play a crucial role in detecting faults that may not be visible to the naked eye, such as soldering issues or short circuits. Additionally, adherence to industry standards, such as IPC specifications, ensures that manufacturers maintain a consistent level of quality. By integrating these practices into their manufacturing processes, companies can effectively minimize errors and promote product integrity, ultimately establishing a reputation for excellence in a competitive market.

Key Quality Control Processes for Circuit Boards

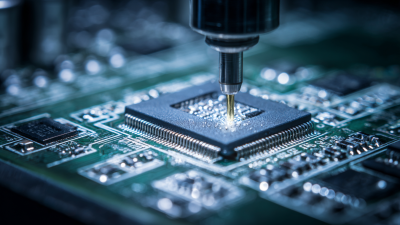

Quality control (QC) plays a pivotal role in circuit board manufacturing, ensuring that each product meets stringent industry standards. Key quality control processes encompass several critical stages, including incoming material inspection, in-process monitoring, and final testing. According to a report by IPC (Association Connecting Electronics Industries), effective QC processes can reduce defects by up to 80%, significantly enhancing overall product reliability.

One of the essential QC methods involves Automated Optical Inspection (AOI), which evaluates the assembled circuit boards for defects such as solder joint issues or component misalignment. Data indicates that implementing AOI systems can detect around 90% of potential faults before the product moves to the final testing stage, thereby saving manufacturers time and resources. Additionally, conducting rigorous functionality tests simulating real-world conditions is vital; a study by the Electronics Manufacturing Services (EMS) industry estimates that companies employing comprehensive testing protocols improve their operational efficiency by 30%.

Furthermore, real-time process control is increasingly being adopted to monitor production metrics continuously. With industry projections indicating that more than 60% of circuit board failures are linked to manufacturing errors, the investment in advanced QC technologies not only optimizes production but also instills confidence in end-users regarding the product's durability and performance.

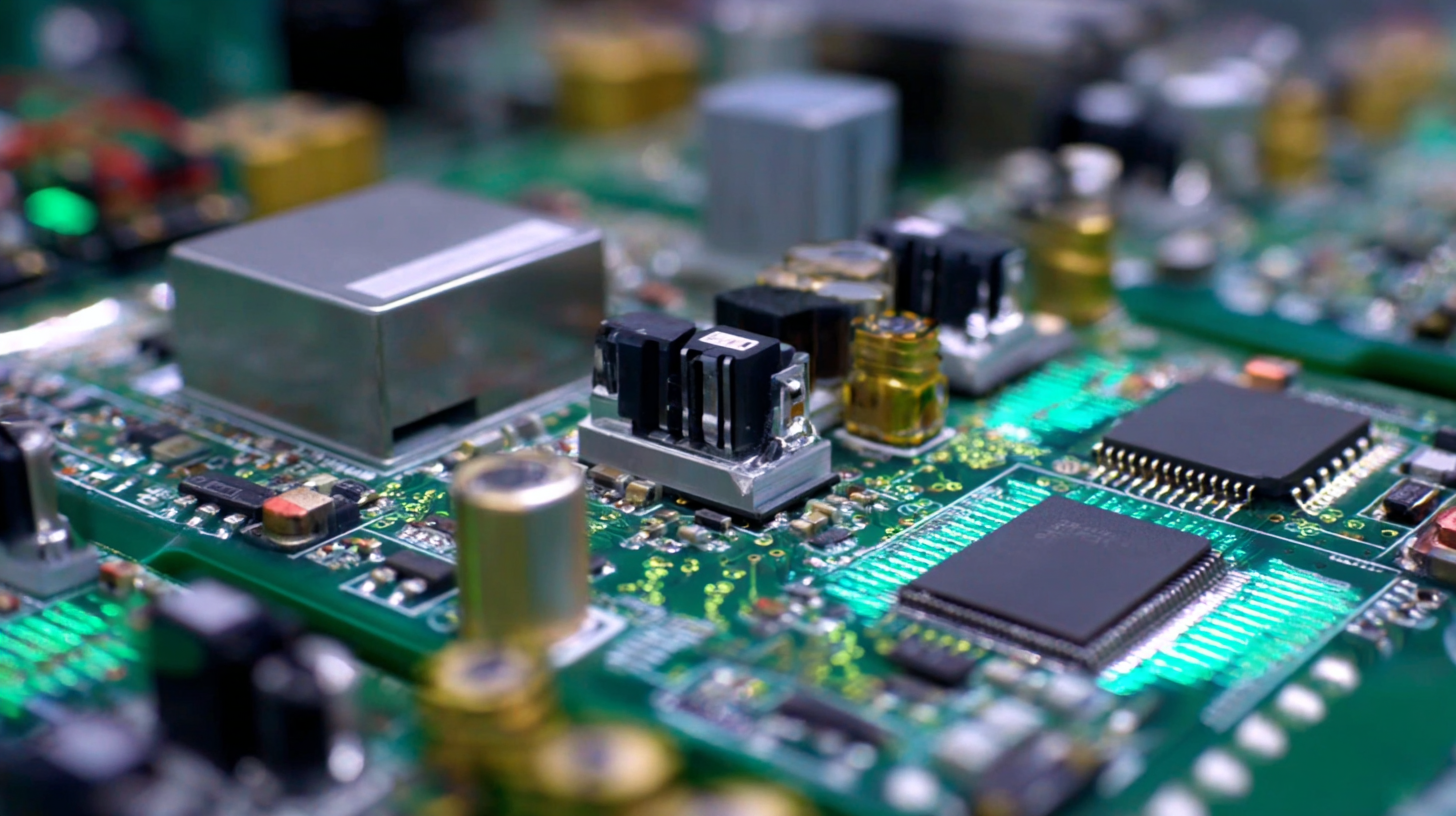

Common Quality Control Challenges in Circuit Board Production

Quality control (QC) is paramount in circuit board manufacturing, yet various challenges can complicate the process. One common issue is the inconsistency in material quality. Fluctuations in the quality of raw materials can lead to defects in the final product, affecting performance and reliability. To mitigate this, manufacturers should establish strong relationships with suppliers and implement strict incoming quality inspections. Regular audits and a robust quality assurance framework can help ensure that the materials meet the necessary standards.

Another significant challenge in quality control is the complexity of circuit board designs. With increasingly intricate layouts, it becomes more challenging to detect and rectify errors during the production process. Utilizing automated optical inspection (AOI) systems can greatly enhance error detection, allowing for quicker remediation of issues before they escalate. Additionally, investing in simulation software can help engineers predict potential design flaws before physical production begins, improving overall quality.

Lastly, human error remains a persistent issue in the manufacturing process. Comprehensive training programs for personnel can reduce mistakes significantly. Incorporating regular training sessions and creating a culture of continuous improvement ensures that workers are well-equipped to uphold quality standards. Emphasizing accountability and providing feedback further enhances the quality control process, leading to superior circuit board manufacturing outcomes.

Benefits of Implementing Rigorous Quality Control Standards

In the fast-paced world of circuit board manufacturing, implementing rigorous quality control standards offers significant advantages that can transform business operations. Quality control not only ensures the reliability and performance of circuit boards but also minimizes the risk of defects that could lead to costly recalls and warranty claims. By adhering to a comprehensive quality management framework, manufacturers can identify issues early in the production process, thereby reducing waste and enhancing overall efficiency.

Emphasizing Total Quality Management (TQM) in circuit board production fosters a culture of continuous improvement. This approach encourages employees at all levels to focus on quality, resulting in higher productivity and better alignment with customer specifications. As a result, enhanced customer satisfaction becomes a natural outcome, as businesses are able to deliver products that meet or exceed expectations. Ultimately, rigorous quality control not only protects a manufacturer's reputation but also drives long-term success in a competitive market.

Future Trends in Quality Control for Circuit Board Manufacturing

As the circuit board manufacturing industry evolves, the importance of quality control (QC) becomes ever more pronounced. Future trends indicate a significant integration of AI and machine learning to automate and enhance QC processes. According to a recent report by Research and Markets, the global market for AI in manufacturing is projected to reach $16.7 billion by 2026, growing at a CAGR of 48.5%. This advancement allows for real-time monitoring and predictive analytics, which can drastically reduce defects and manufacturing downtime by up to 30%.

Furthermore, the adoption of Industry 4.0 technologies is shaping the QC landscape. By implementing IoT sensors within the manufacturing process, companies can obtain actionable insights into their production lines. A study from Gartner shows that organizations leveraging IoT for quality monitoring experience a 25% improvement in product quality. The shift towards automated, data-driven QC allows manufacturers to ensure higher standards and expedite their response to potential issues, ultimately enhancing customer satisfaction and driving competitive advantage in an increasingly complex market.

Related Posts

-

Top 10 Circuit Board Fabrication Manufacturers from China at the 137th Canton Fair

-

Solutions for Exceptional Circuit Board Fabrication Techniques

-

Understanding Global Industry Standards for Best PCB Printed Circuit Boards in Modern Manufacturing

-

Discover Pcb Circuit Board Innovations at the Record Breaking 137th Canton Fair in Guangzhou

-

Understanding Industry Production Standards for Best Circuit Board Assembly Techniques

-

Global Leaders in PCB Assembly: Unlocking Top Quality and Efficiency for Worldwide Exports

Phone

WhatsApp

WhatsAppEmail

Offer Electronics Manufacturing All-in-One

PCBONLINE® is a registered trademark or service mark of pcb online limited or its affiliates.

Copyright © 2001-2024 Pcb Online Limited. All rights reserved