- PCB Assembly

- PCB Fab

- Resources

- Company

- Blog

Global Solutions in Circuit Board Assembly: Embracing Excellence from China

In the rapidly evolving landscape of technology, Circuit Board Assembly (CBA) has emerged as a pivotal process that underpins the functionality of countless electronic devices. As businesses worldwide seek competitive advantages through efficiency, cost-effectiveness, and precision, the spotlight has turned to China, a global leader in CBA services. This blog aims to guide you through the myriad solutions available in circuit board assembly from China, highlighting not only the excellence of its manufacturing capabilities but also the innovative practices that have set the country apart in the global marketplace.

From advanced technology and skilled labor to stringent quality control measures, we will explore how embracing these solutions can significantly enhance your product development and ultimately drive your business success. Join us as we delve into the factors making China the go-to destination for high-quality Circuit Board Assembly, ensuring you stay ahead in a competitive industry.

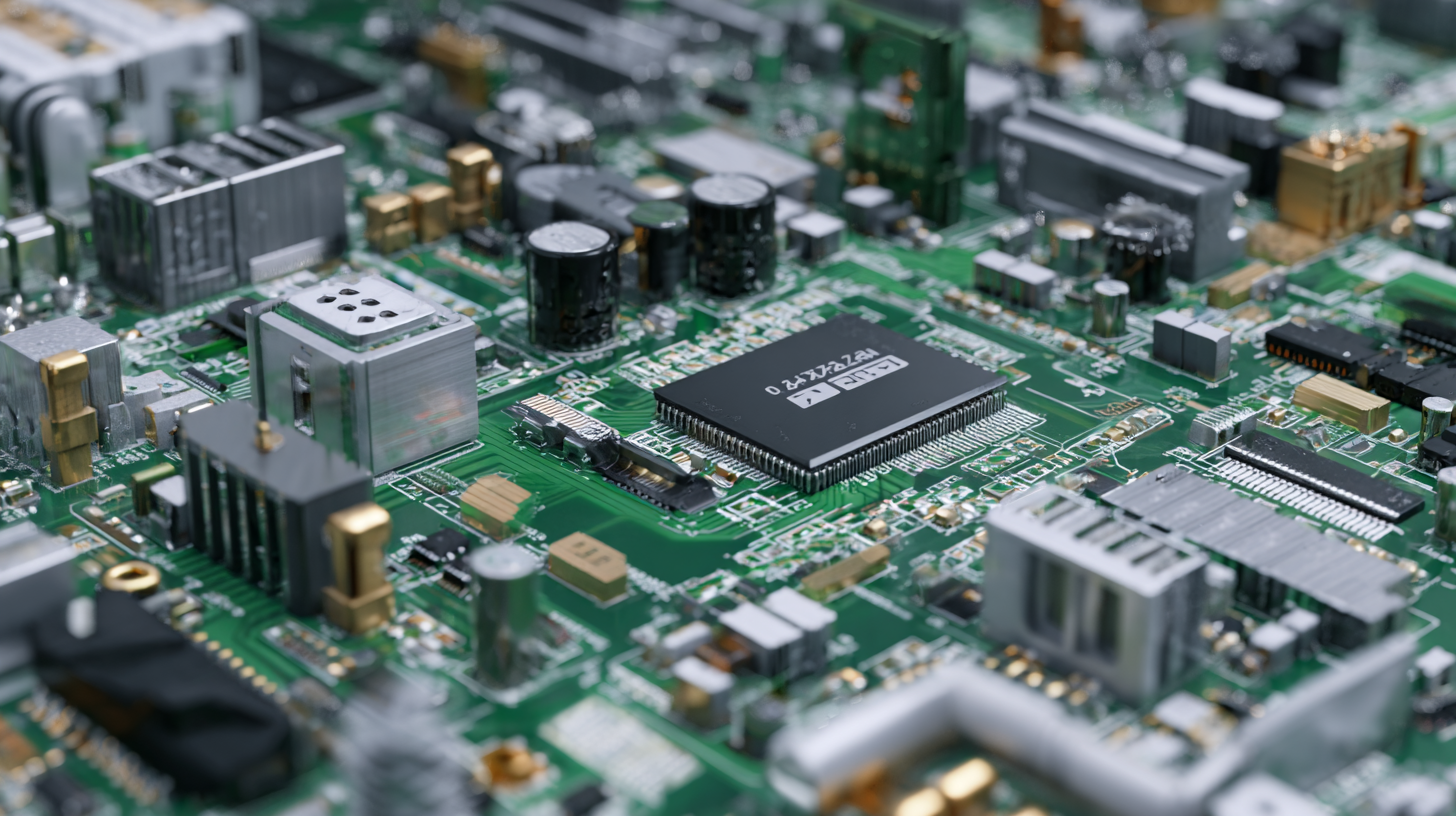

Understanding the Importance of Circuit Board Assembly in Modern Electronics

In today's rapidly advancing technological landscape, circuit board assembly (CBA) stands as a cornerstone of modern electronics. Its significance extends beyond mere functionality; CBA is integral to the performance, reliability, and longevity of electronic devices. From smartphones to medical devices, the complexity of circuit boards demands precision and expertise in their assembly. Each connection, solder joint, and component placement must be executed with meticulous care, as even minor discrepancies can lead to failures or malfunctions.

China has emerged as a global leader in circuit board assembly, leveraging its vast manufacturing capabilities and skilled workforce. By embracing cutting-edge technologies and quality control measures, Chinese manufacturers are setting the standards for excellence in the industry. The importance of this sector cannot be overstated, as the reliability of electronic products directly impacts user experience and safety. As manufacturers worldwide seek to optimize their supply chains and enhance product quality, understanding the intricacies of circuit board assembly becomes crucial for staying competitive in the dynamic electronics market.

Exploring China’s Leading Role in Global Circuit Board Manufacturing

China has firmly established itself as a leader in the global circuit board manufacturing landscape. The country boasts a combination of cutting-edge technology, a skilled workforce, and the ability to scale production quickly, making it an attractive hub for companies seeking excellence in circuit board assembly. With numerous specialized factories spread across major industrial regions, China excels in producing a wide array of circuit boards, from simple designs to complex multilayer configurations.

Moreover, China's commitment to innovation is evident in its continuous investment in research and development. This focus not only enhances the quality of the products but also improves the efficiency of the manufacturing processes. As global demand for electronics surges, China's manufacturers are increasingly adopting advanced automation and smart manufacturing technologies. This agility allows them to respond swiftly to market trends and customer needs, further solidifying their pivotal role in the global supply chain.

Global Circuit Board Manufacturing Output (in Billion USD)

Key Factors to Consider When Choosing Circuit Board Assembly Providers

When selecting circuit board assembly (CBA) providers, several key factors must be considered to ensure a successful partnership, especially given the dominance of China in this industry. According to reports, the global electronic contract manufacturing and design services market was valued at approximately USD 515.1 billion in 2022, highlighting the immense scale and importance of efficient manufacturing solutions. A crucial aspect of this optimization involves understanding life-cycle accounting and cost optimization techniques, such as resource cleansheet analysis, which aids manufacturers in balancing cost reductions with environmental considerations.

Furthermore, the rise of automation and robotics is reshaping the landscape of PCB assembly. The 2022 McKinsey Global Industrial Robotics Survey indicates that industrial companies are poised to make substantial investments in these technologies. This shift not only improves production efficiency but also enhances precision in assembly processes. With China's leading position in PCB manufacturing, characterized by lower costs and advanced capabilities, understanding these trends is essential for businesses looking to choose the right CBA provider. By evaluating potential partners through the lens of cost optimization and technological advancements, companies can make informed decisions that support their long-term success in a competitive market.

Quality Assurance Practices in Chinese Circuit Board Assembly

In the rapidly evolving world of electronics, quality assurance in circuit board assembly has emerged as a cornerstone of success, particularly in China. Leveraging advanced technologies and rigorous testing protocols, manufacturers in this region have set high standards for reliability and performance. Emphasizing a systematic approach, these companies utilize techniques such as automated optical inspection (AOI) and in-circuit testing (ICT) to identify defects early in the production process, ensuring that only products meeting stringent specifications proceed to the next stages.

Moreover, China's commitment to quality assurance extends beyond production lines. Many assembly facilities adopt international quality standards, such as ISO 9001, to enhance their operational frameworks. Training programs focused on the latest industry practices empower employees to uphold these standards consistently. By embedding a culture of excellence and continuous improvement, Chinese manufacturers not only enhance customer satisfaction but also boost their competitiveness in the global market. This dedication to quality assurance practices enables them to deliver circuit boards that not only meet but exceed the demanding requirements of diverse industries.

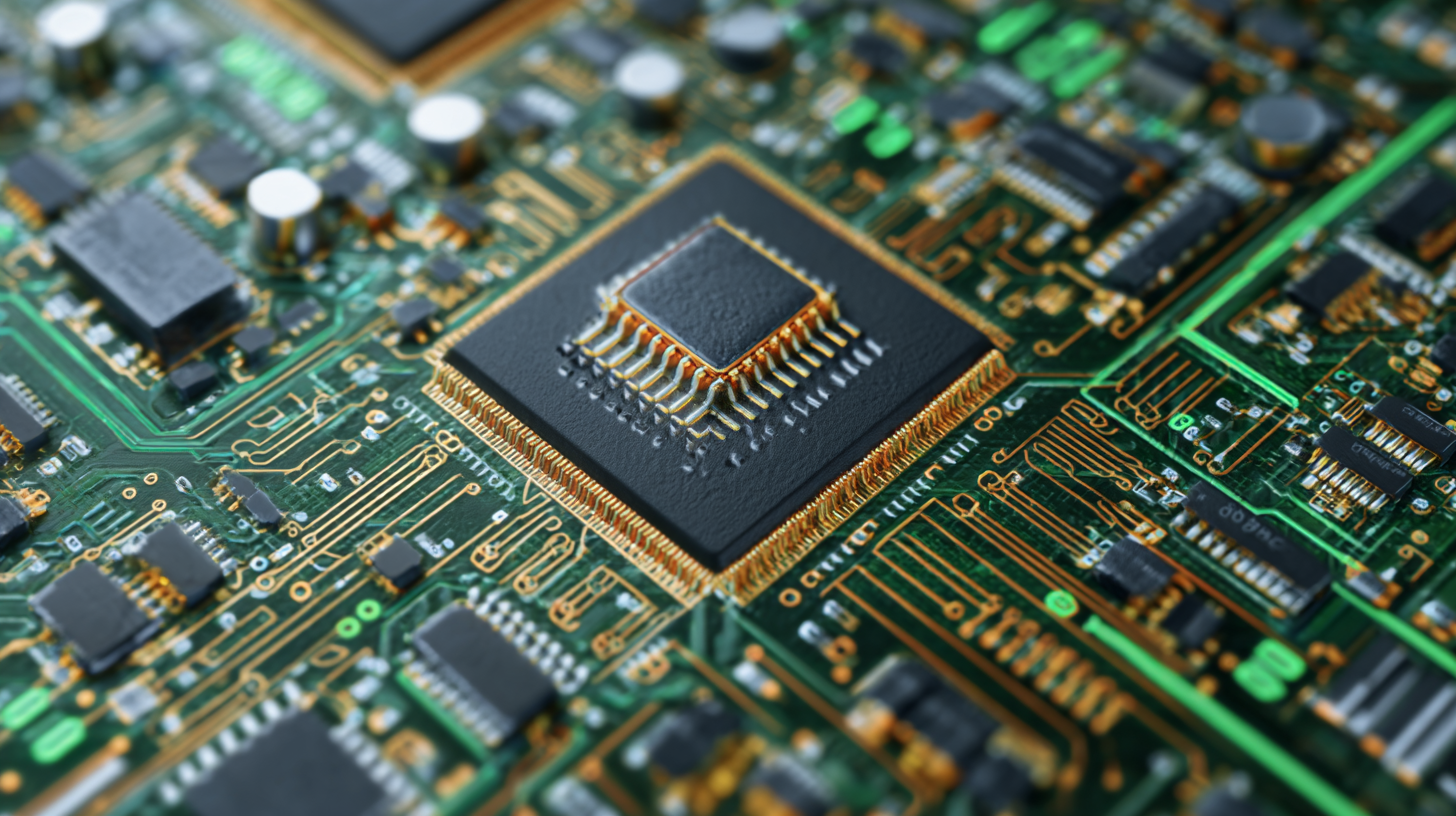

The Future of Circuit Board Assembly: Innovations and Trends Emerging from China

The future of circuit board assembly is being reshaped by a wave of innovations and trends emerging from China. As the nation continues to invest heavily in advanced manufacturing technologies, companies are adopting automation, artificial intelligence, and machine learning to optimize their production processes. This technological evolution allows for precision assembly, reduced lead times, and improved quality control, positioning China as a leader in the global circuit board assembly market.

Moreover, sustainability is becoming a driving force in China's manufacturing sector. With growing awareness and regulatory pressures, businesses are integrating eco-friendly practices into their operations, from reducing waste during production to utilizing renewable energy sources. These sustainable methods not only cater to the increasing demand for environmentally responsible manufacturing but also pave the way for long-term cost savings and operational efficiency. As a result, China's circuit board assembly industry is at the forefront of not only meeting technological demands but also embracing a greener future, setting a new benchmark for global standards.

Phone

WhatsApp

WhatsAppEmail

Offer Electronics Manufacturing All-in-One

PCBONLINE® is a registered trademark or service mark of pcb online limited or its affiliates.

Copyright © 2001-2024 Pcb Online Limited. All rights reserved