- PCB Assembly

- PCB Fab

- Resources

- Company

- Blog

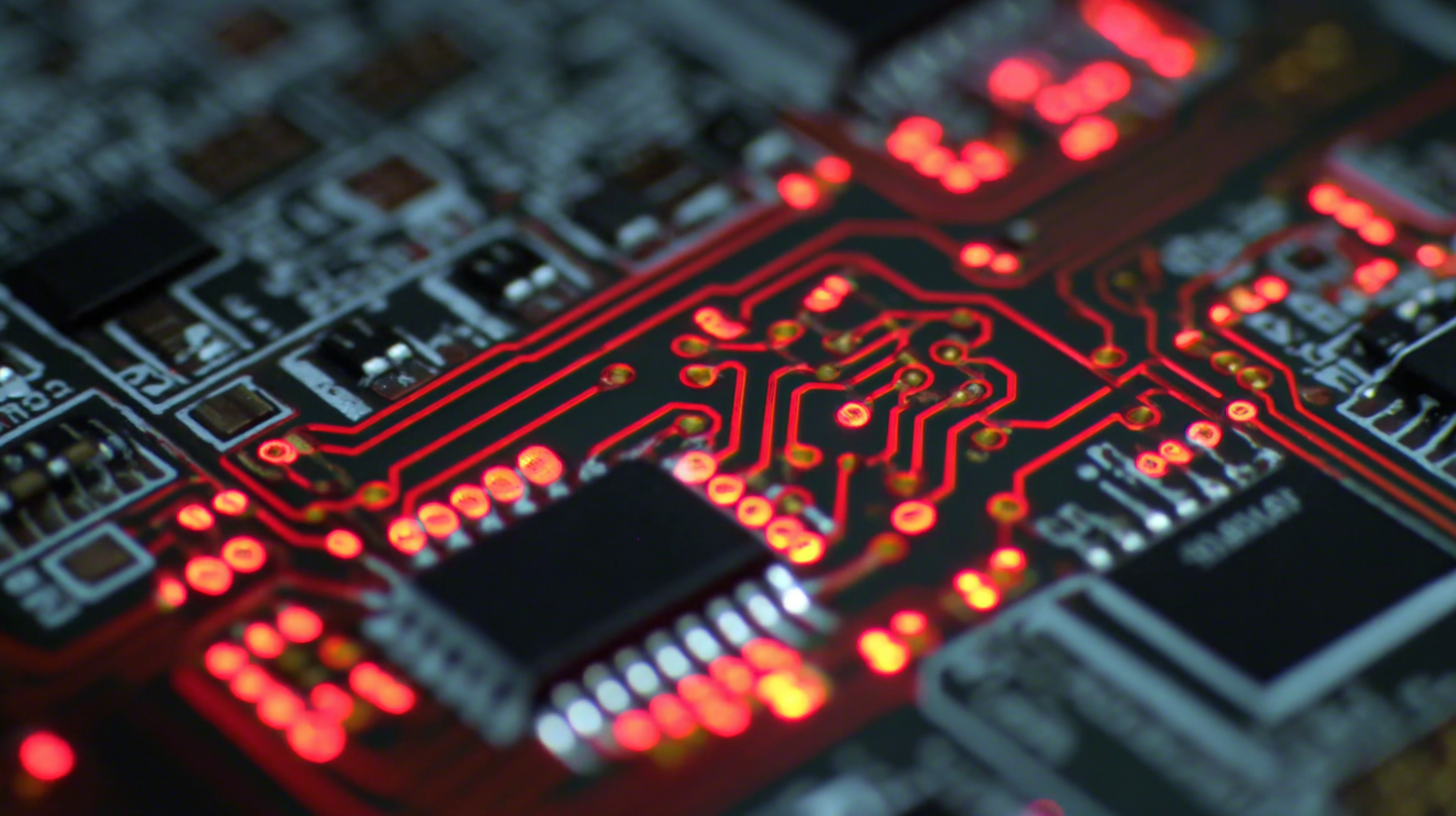

Exploring the Future of Best Led Circuit Board Innovations and How to Integrate Them by 2025

As we embark on a journey toward 2025, the landscape of LED circuit board innovations is evolving at a remarkable pace, driven by advancements in technology and increasing demand for energy-efficient lighting solutions. According to a recent market analysis by Research and Markets, the global LED circuit board market is expected to grow at a CAGR of over 14% through the next five years, underscoring the critical role these components will play in various applications, from consumer electronics to automotive lighting.

This blog aims to explore the future of LED circuit board innovations, highlighting key trends, emerging technologies, and best practices for integration. By understanding the current trajectory of this industry, manufacturers and consumers alike can prepare to leverage the full potential of LED circuit boards, ensuring both sustainability and performance efficiency in their products.

The Role of LEDs in Sustainable Circuit Board Design: Trends and Innovations for 2025

The increasing focus on sustainability in technology has placed LEDs at the forefront of innovative circuit board design. By 2025, we can expect to see a significant shift in how LEDs are integrated into circuit boards, with an emphasis on energy efficiency and reduced environmental impact. Advances in LED technology, such as organic LEDs (OLEDs) and miniaturization, are enabling creators to design more compact and versatile circuit boards that not only consume less power but also generate less heat. This transition represents a crucial step toward creating eco-friendly electronics that align with global sustainability goals.

Moreover, as manufacturers look to reduce their carbon footprint, the integration of LEDs in circuit boards allows for smarter energy management systems. Innovations like tunable lighting and adaptive circuits can optimize energy usage based on real-time data, promoting efficient performance without sacrificing brightness or quality. Circuit boards utilizing LEDs are also expected to incorporate recyclable materials, addressing the growing issue of electronic waste. As these trends evolve, they will pave the way for a new era of circuit board design that prioritizes both functionality and environmental responsibility.

Exploring the Future of Best Led Circuit Board Innovations and How to Integrate Them by 2025

| Innovation Area | Description | Sustainability Impact | Projected Adoption Rate by 2025 |

|---|---|---|---|

| Flexible Circuit Boards | Circuit boards that can bend and flex, allowing for innovative designs in compact spaces. | Reduces material waste and enhances recyclability. | 45% |

| Biodegradable Materials | Using materials that decompose naturally to minimize environmental impact. | Significantly lowers landfill contributions. | 30% |

| Integrated LED Systems | LEDs built directly into circuit boards for improved efficiency and design flexibility. | Increases energy efficiency and reduces power consumption. | 50% |

| Smart Sensors | Sensors that adapt to their environment, providing real-time feedback for optimal efficiency. | Enhances energy conservation and operational efficiency. | 40% |

| Advanced Thermal Management | Innovative cooling solutions that prevent overheating and enhance performance. | Extends the lifespan of circuit boards and minimizes waste. | 35% |

Advancements in Thermal Management Techniques for LED Circuit Boards

As LED technology continues to evolve, advancements in thermal management techniques for LED circuit boards are becoming increasingly critical. According to a recent report by MarketsandMarkets, the thermal management market for LED applications is projected to grow from $3.2 billion in 2020 to $5.4 billion by 2025, at a compound annual growth rate (CAGR) of 10.7%. This growth underscores the importance of efficient heat dissipation in enhancing the performance and lifespan of LED products.

One of the most innovative thermal management techniques involves the use of advanced materials such as graphene and ceramic substrates, which offer superior thermal conductivity compared to traditional materials. Research published in the Journal of Electronic Materials indicates that integrating these materials can reduce thermal resistance significantly, thereby improving overall LED efficiency. Furthermore, the implementation of active thermal management systems, such as microchannel cooling, is gaining traction. These systems achieve optimal thermal performance, enabling LEDs to operate at higher power levels without compromising reliability. As we move towards 2025, these innovations will play a pivotal role in shaping the performance and efficiency of LED circuit boards in various applications.

Innovations in LED Circuit Board Thermal Management (2023-2025)

Integrating Smart Technology in LED Circuit Boards: Opportunities and Challenges

As the demand for smarter and more efficient lighting solutions grows, integrating advanced technology into LED circuit boards presents both exciting opportunities and formidable challenges. By 2025, the global smart lighting market is expected to reach approximately $39 billion, with LED lighting expected to dominate due to its energy efficiency and longer lifespan. This paradigm shift not only involves the incorporation of smart sensors and IoT connectivity but also necessitates addressing compatibility with existing systems, which can complicate the integration process.

One of the significant challenges lies in standardizing smart technology for LED circuit boards. According to a report by MarketsandMarkets, the rapid advancement in LED technology suggests that integration must occur across various platforms, creating a pressing need for universally accepted protocols. Security concerns also emerge, as more connected devices increase the risk of cyber threats, making it imperative for manufacturers to prioritize robust cybersecurity measures. Ultimately, while the path to integrating smart technology in LED circuit boards is paved with challenges, the potential for enhanced energy management and improved user experience creates a compelling case for continued innovation in this field.

Comparative Analysis of Alternative Materials for Enhanced LED Circuit Board Efficiency

The search for improved efficiency in LED circuit boards has led to a comparative analysis of various alternative materials. Traditional materials like epoxy resins and aluminum substrates have served well for years, but innovative options are emerging that promise enhanced performance. For instance, materials such as ceramic-based substrates are gaining traction due to their superior thermal conductivity and longer lifespan, which are critical for modern lighting solutions.

When selecting materials for LED circuit boards, consider the thermal management capabilities essential for maintaining optimal performance. Utilizing materials that maximize heat dissipation can prevent overheating and improve the longevity of LEDs. Additionally, experimenting with hybrid materials that combine the best properties of different substances can lead to groundbreaking advancements.

Tip: Always prioritize materials that offer high dielectric strength to maintain circuit integrity and prevent failure under different operating conditions. Test prototypes with various coatings to enhance durability and efficiency. Another approach is to stay updated with industry trends, as new materials and technologies can emerge rapidly, offering innovative solutions for LED circuit board integration by 2025.

Future Market Predictions: Growth and Development of LED Circuit Board Technologies by 2025

The landscape of LED circuit board technologies is poised for significant transformation by 2025. As industries increasingly lean toward energy-efficient options, the demand for advanced LED solutions is projected to soar. Market predictions suggest a compound annual growth rate (CAGR) that will reflect the ongoing evolution in areas such as miniaturization and smart integration. Innovative designs will not only enhance energy efficiency but also improve lighting quality and lifespan, positioning LED technology at the forefront of sustainable solutions.

To thrive in this evolving market, businesses must prioritize staying informed of the latest advancements. Tip: Regularly attend industry conferences and exhibitions to network with key players and gain insights into emerging trends. Additionally, investing in research and development capacities can be pivotal in ensuring a competitive edge. Tip: Collaborate with universities and tech hubs to access cutting-edge research that can lead to innovative product features.

As manufacturers refine their production processes and incorporate smart technologies, the integration of IoT within LED circuits will become increasingly mainstream. Tip: Consider adopting modular designs that allow for easier upgrades and scalability in your products. This adaptability will not only cater to diverse customer needs but also prepare businesses for future technological advancements in the LED circuit board arena.

Phone

WhatsApp

WhatsAppEmail

Offer Electronics Manufacturing All-in-One

PCBONLINE® is a registered trademark or service mark of pcb online limited or its affiliates.

Copyright © 2001-2024 Pcb Online Limited. All rights reserved