- PCB Assembly

- PCB Fab

- Resources

- Company

- Blog

Solutions for Exceptional Circuit Board Fabrication Techniques

In the rapidly evolving realm of electronics, the demand for exceptionally crafted circuit boards has surged, driving the need for innovative Circuit Board Fabrication techniques. According to a recent report by ResearchAndMarkets, the global printed circuit board (PCB) market is projected to grow from USD 60.36 billion in 2021 to USD 85.80 billion by 2026, reflecting a compound annual growth rate (CAGR) of 6.97%. This dramatic increase underscores the critical importance of leveraging advanced fabrication methods to enhance performance, reduce costs, and meet the stringent demands of contemporary technology.

As industries adopt more complex designs and functionalities to cater to the rise of IoT, automotive, and consumer electronics, finding solutions for circuit board fabrication becomes paramount. This blog will explore cutting-edge techniques and strategies that not only optimize manufacturing processes but also ensure high-quality outputs essential for modern applications.

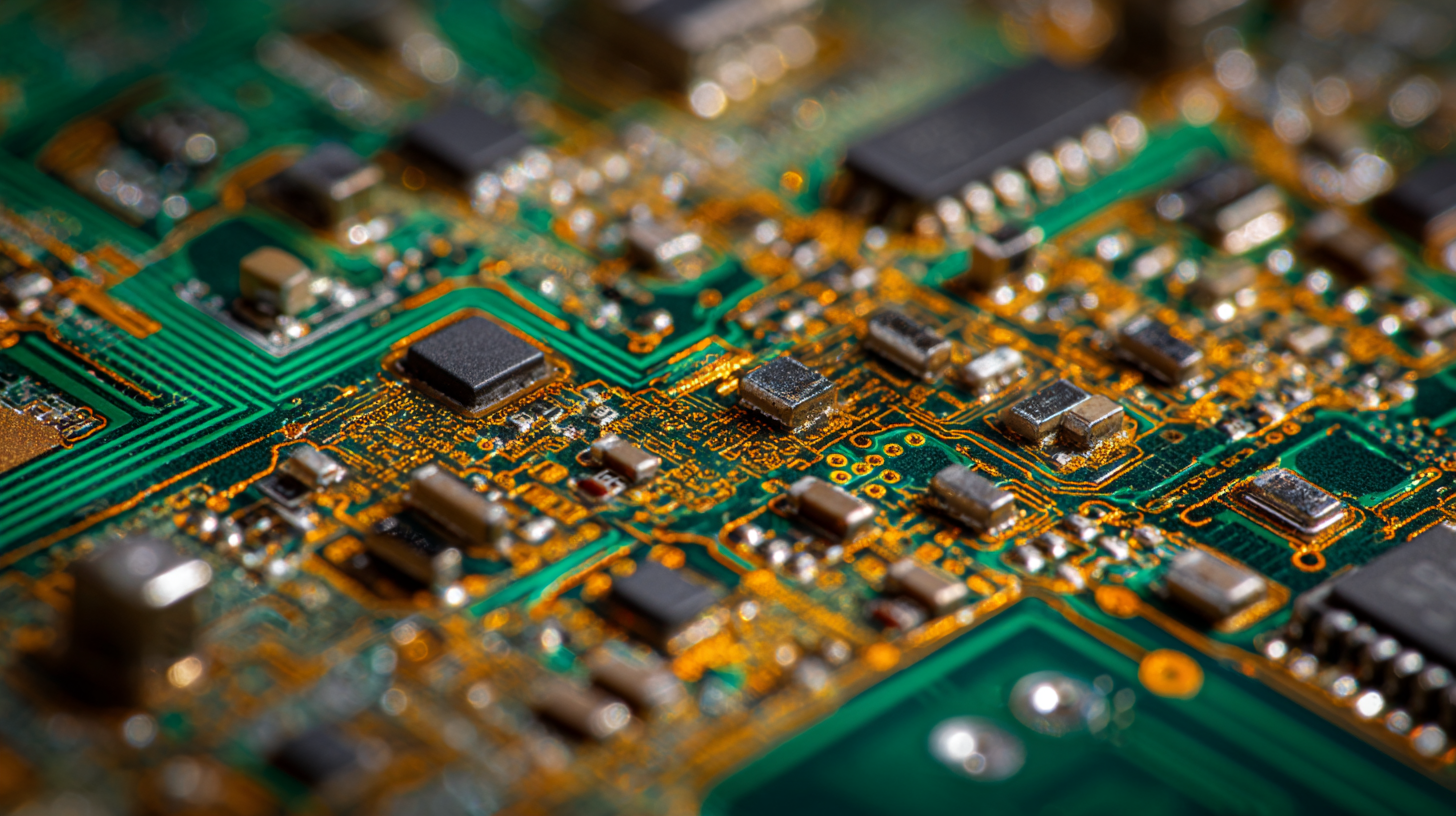

Innovative Materials Driving Advanced Circuit Board Fabrication

In the rapidly evolving electronics industry, advanced circuit board fabrication techniques are increasingly influenced by innovative materials. According to a report by MarketsandMarkets, the global printed circuit board (PCB) market is projected to reach $78.66 billion by 2025, driven by the growing demand for high-performance electronics across automotive, consumer electronics, and telecommunications sectors. As manufacturers strive for sustainability and enhanced performance, materials such as low-loss laminates and flexible substrates are gaining traction.

One of the most notable trends is the adoption of hybrid materials that combine traditional resin systems with advanced thermoplastic and ceramic composites. These materials not only improve thermal conductivity but also enhance the durability and reliability of circuit boards, which is crucial for the miniaturization of electronic devices. A study by IPC found that using high-frequency laminates can reduce signal loss by up to 30%, making them essential for high-speed applications. As the industry continues to innovate, these advancements in materials will play a pivotal role in shaping the future of circuit board fabrication, enabling the development of smaller, faster, and more efficient electronic products.

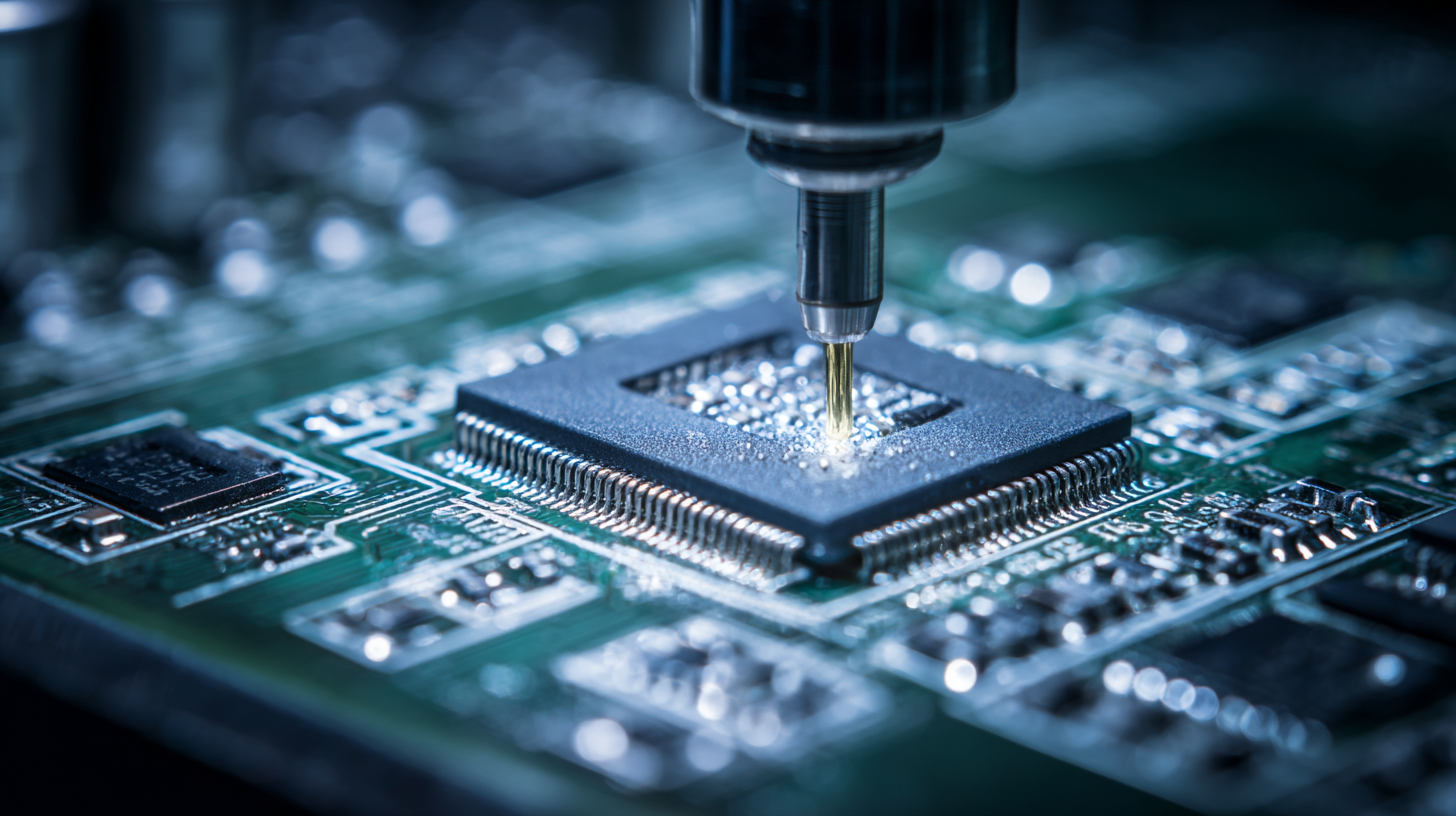

Precision Engineering: Techniques for High-Quality PCB Production

In the fast-paced electronics industry, precision engineering is pivotal for high-quality PCB production. As reported by IPC, the global market for PCBs is projected to reach $80 billion by 2026, driven by the increasing demand for advanced electronic components in sectors like automotive, aerospace, and telecommunications. Manufacturing techniques that prioritize precision, such as laser direct imaging and automated optical inspection, are critical for achieving the tight tolerances required in today's high-performance applications.

Moreover, advancements in materials science have paved the way for improved substrate materials that enhance performance and reliability. For instance, high-frequency laminates exhibit superior electrical characteristics, which are essential for high-speed PCBs utilized in 5G technology. A report from Research and Markets suggests that the adoption of advanced PCB materials will grow at a CAGR of 6.2% between 2023 and 2028, highlighting the industry's shift towards innovation in fabrication techniques. Embracing these state-of-the-art methods not only ensures compliance with industry standards but also reduces production costs through improved efficiency and yield rates.

PCB Fabrication Techniques and Production Quality

This chart illustrates the relationship between various PCB fabrication techniques and their corresponding production quality ratings based on industry standards.

Sustainable Practices in Circuit Board Manufacturing

In the rapidly evolving field of circuit board manufacturing, sustainable practices have transcended from being optional to essential. According to a report by the International Telecommunication Union, the global electronics industry contributes approximately 12% of the world's total carbon emissions, highlighting the urgent need for greener approaches. Companies are increasingly adopting eco-friendly materials and processes to mitigate environmental impact. For instance, biopolymers and recycled materials are being integrated into PCB designs, significantly reducing the carbon footprint throughout the product lifecycle.

Additionally, advanced manufacturing techniques, such as additive manufacturing and multi-layered PCB designs, are paving the way for more sustainable production methods. A study by the Engineering Research Institute reveals that implementing these technologies can lower the energy consumption of PCB fabrication by up to 30%. Clean manufacturing initiatives, such as minimizing waste and promoting energy efficiency, have also been proven to enhance profitability while catering to eco-conscious consumers.

As the demand for sustainable practices grows, circuit board manufacturers who prioritize these methods will not only contribute to environmental preservation but also position themselves competitively in a market that increasingly values sustainability.

Global Impact of Chinese PCB Technology on Worldwide Industries

The global landscape of printed circuit board (PCB) technology has been significantly influenced by advancements from Chinese manufacturers. In 2022, the Chinese PCB market was valued at approximately $35 billion, making up over 40% of the global supply. This dominance can be attributed to China's robust manufacturing capabilities, cost-effective production processes, and an extensive supply chain that supports rapid innovation. According to a report by Research and Markets, the Chinese PCB industry is expected to grow at a CAGR of 6.8% between 2023 and 2028, reflecting its critical role in various sectors such as telecommunications, consumer electronics, and automotive industries.

Moreover, the impact of Chinese PCB technology transcends its borders, shaping worldwide industries through enhanced efficiency and reliability. For instance, the integration of advanced manufacturing techniques, such as HDI (High-Density Interconnector) boards, has allowed companies globally to produce smaller, more powerful devices. A study from IPC revealed that 72% of electronics manufacturers cite the quality of PCB technology as a key factor influencing their product performance. As businesses continue to adopt these advanced solutions, it is clear that China's innovations are setting new standards for quality and competition in the PCB market, driving advancements that resonate across the global economy.

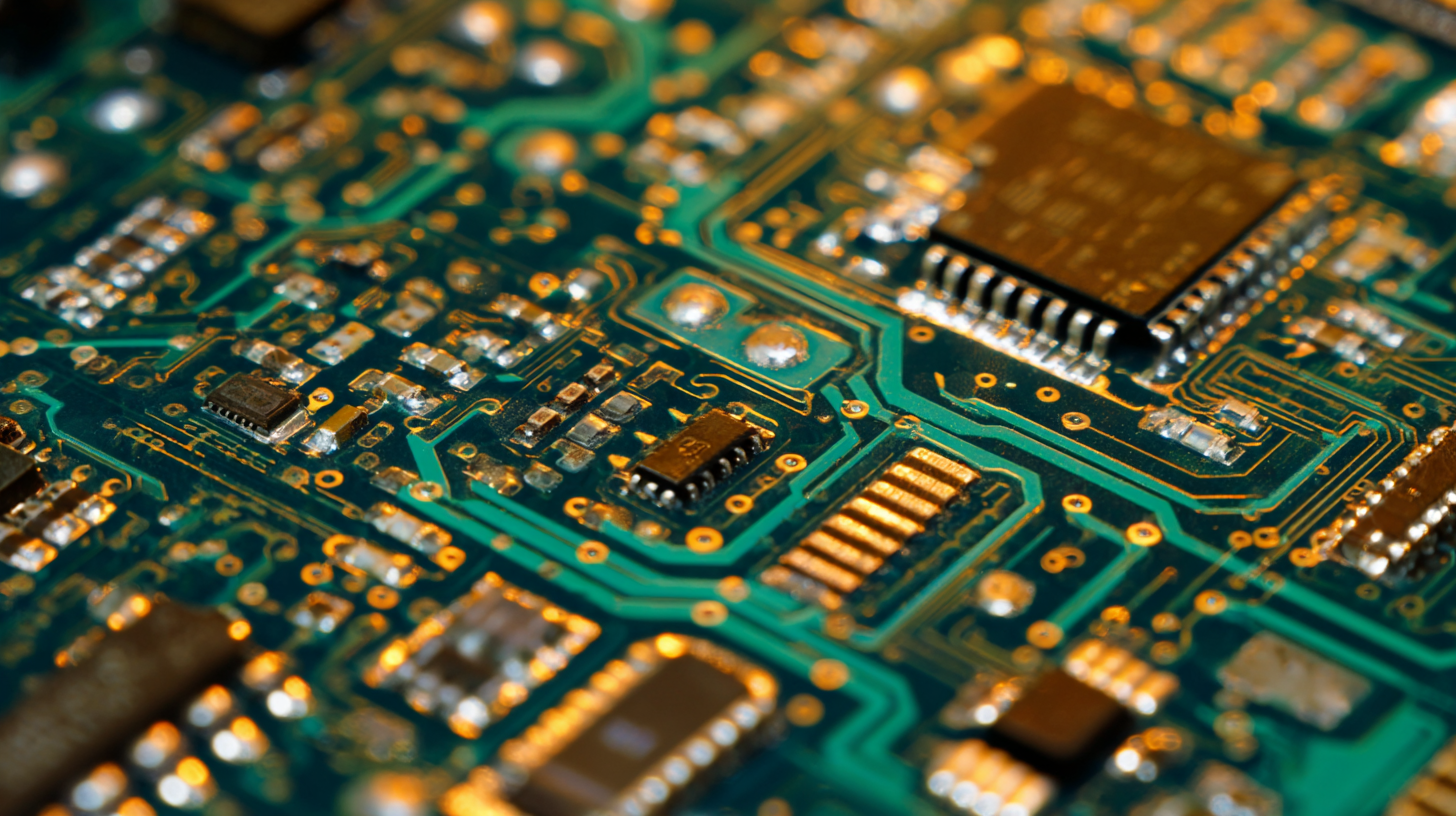

Future Trends in Circuit Board Fabrication: What to Expect Next

The future of circuit board fabrication is poised for significant growth and innovation, driven by the increasing demand for advanced electronic devices. According to the Printed Circuit Boards Global Market Report 2024, the market was valued at $67.9 billion in 2023, with projections indicating an increase to $70.9 billion in 2024 and a remarkable rise to $92.4 billion in the near future. This expansion reflects a robust appetite for high-quality, efficient circuit boards across various sectors, spurred by emerging technologies such as artificial intelligence and the burgeoning internet of things.

Coupled with this growth is the evolution of circuit board assembly techniques. The Printed Circuit Board Assembly Market is expected to reach approximately $39.44 billion in 2024, with continued growth anticipated as manufacturers adopt more sophisticated production methods and materials. In particular, the Substrate-Like PCB segment is projected to grow significantly, reaching $7.16 billion by 2031, representing a compound annual growth rate (CAGR) of 13.4%. This evolution underscores the importance of innovation in fabrication techniques as companies strive to meet the increasing performance demands of complex electronic applications. As we look ahead, embracing these emerging trends and investing in advanced manufacturing capabilities will be critical for firms aiming to thrive in the competitive landscape of electronics.

Solutions for Exceptional Circuit Board Fabrication Techniques - Future Trends in Circuit Board Fabrication: What to Expect Next

| Technology | Key Features | Benefits | Expected Adoption Rate (2025) |

|---|---|---|---|

| 3D Printing | Additive manufacturing for PCB | Reduced waste, faster prototyping | 35% |

| Flexible PCBs | Bendable and lightweight circuits | Increased design freedom, durability | 50% |

| High-frequency PCB Fabrication | Materials for RF/ microwave applications | Improved signal integrity | 40% |

| Advanced Surface Mount Technology (SMT) | Miniaturization and precision assembly | Higher component density, smaller size | 60% |

| Embedded Components | Integrating components within the board | Space-saving, enhanced performance | 45% |

Phone

WhatsApp

WhatsAppEmail

Offer Electronics Manufacturing All-in-One

PCBONLINE® is a registered trademark or service mark of pcb online limited or its affiliates.

Copyright © 2001-2024 Pcb Online Limited. All rights reserved