- PCB Assembly

- PCB Fab

- Resources

- Company

- Blog

How to Choose the Right Partner for Your Circuit Board Manufacturing Needs

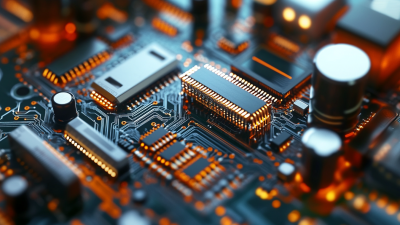

In the fast-paced world of technology, selecting the right partner for your circuit board manufacturing needs is a critical decision that can significantly impact your project’s success. With numerous suppliers vying for your attention, it’s essential to navigate through the options carefully to find a partner that aligns with your specific requirements. The circuit board manufacturing process involves intricate designs and high precision, making it imperative to collaborate with a provider that not only possesses advanced technical capabilities but also shares your commitment to quality and innovation.

In the fast-paced world of technology, selecting the right partner for your circuit board manufacturing needs is a critical decision that can significantly impact your project’s success. With numerous suppliers vying for your attention, it’s essential to navigate through the options carefully to find a partner that aligns with your specific requirements. The circuit board manufacturing process involves intricate designs and high precision, making it imperative to collaborate with a provider that not only possesses advanced technical capabilities but also shares your commitment to quality and innovation.

This blog will guide you through the essential factors to consider, helping you make an informed choice that can enhance your production efficiency and ensure the reliability of your final products. Whether you’re a startup or an established company looking to scale, understanding how to choose the right partner in circuit board manufacturing is vital for future growth and competitive advantage.

Understanding Your Specific Circuit Board Requirements

When selecting a partner for your circuit board manufacturing, understanding your specific requirements is crucial. Begin by assessing the type of circuit boards you need—be it single-sided, double-sided, or multi-layered boards. Each design has its own complexity and cost implications. Additionally, consider the materials required, as different applications may need specific substrates, such as FR-4, aluminum, or flexible materials. This clarity will help you communicate your needs effectively to potential manufacturers.

Beyond the type of boards, evaluate factors like turnaround time, production volume, and quality standards. If your project has tight deadlines, ensure your partner can meet those timelines without compromising quality. Furthermore, look for manufacturers with certifications such as ISO or IPC, which signify adherence to industry standards. Lastly, consider the manufacturer’s experience in your specific industry; a partner familiar with your sector's challenges will be better equipped to meet your needs efficiently. By thoroughly understanding your requirements, you pave the way for a successful partnership that can enhance your product's performance and reliability.

How to Choose the Right Partner for Your Circuit Board Manufacturing Needs

| Requirement Dimension | Considerations | Importance Level |

|---|---|---|

| Design Complexity | Assess the intricacy and layering of the circuit board design. | High |

| Material Type | Determine the required substrate material, such as FR-4, Rogers, etc. | Medium |

| Volume Needs | Estimate the production volume for cost-effectiveness. | High |

| Lead Time | Understand the desired turnaround time for manufacturing. | Medium |

| Testing Capabilities | Evaluate the quality assurance tests performed by the manufacturer. | High |

| Certifications | Check for industry-standard certifications such as ISO, UL. | Medium |

| After-Sales Support | Inquire about support provided post-manufacturing. | Low |

Evaluating the Technical Expertise of Potential Partners

When it comes to selecting a partner for your circuit board manufacturing needs, evaluating their technical expertise is crucial. Technical proficiency serves as a foundation for ensuring that the manufacturing process aligns with your project requirements. Look for partners who have a proven track record in the industry, demonstrating their ability to handle complex designs and varying specifications. A company that continually invests in training and advanced machinery typically indicates a commitment to maintaining their technical edge.

Tip: Request case studies or examples of past projects to assess how potential partners have addressed similar challenges. This will provide insight into their problem-solving capabilities and innovative approaches.

Additionally, consider whether the partner has relevant certifications or adheres to industry standards, which can be a testament to their technical abilities. A partner equipped with certifications like IPC-6012 or ISO 9001 is likely to prioritize quality and consistency in their work.

Tip: Schedule a technical interview to discuss your specific requirements and gauge their familiarity with the latest technologies and trends in circuit board manufacturing. This interaction will help you understand their technical depth and if they can scale according to your needs.

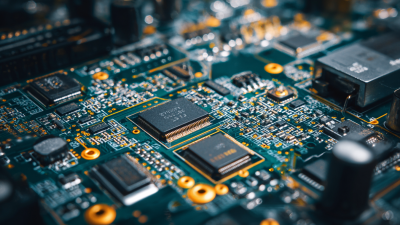

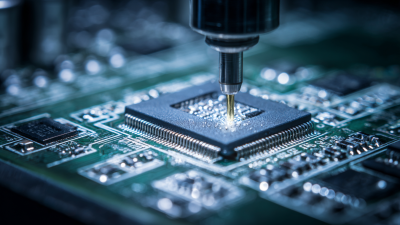

Assessing Production Capabilities and Equipment Quality

When selecting a partner for your circuit board manufacturing needs, assessing their production capabilities and equipment quality is paramount. A reliable manufacturer should possess advanced machinery that meets industry standards and is capable of producing high-quality circuit boards consistently. Ensure to inquire about their technology stack, including the types of printers, routers, and assembly equipment they utilize. The integration of modern automation and precision tools typically indicates a commitment to quality and efficiency.

Additionally, it's crucial to evaluate the manufacturer's production capacity. Does their infrastructure allow for scalability in accordance with your project demands? A partner who can adapt to fluctuations in order sizes—whether you need small batches for prototyping or large volumes for mass production—proves invaluable. Don’t hesitate to request information on their production lead times and their ability to meet deadlines under various circumstances. By carefully examining these aspects, you can choose a partner that aligns closely with your manufacturing goals and ensures high quality in every aspect of your circuit board production.

Production Capabilities Assessment for Circuit Board Manufacturers

This bar chart compares the production capabilities and equipment quality of various factors important in choosing a circuit board manufacturer. The categories assessed include 'Production Speed', 'Quality Assurance', 'Equipment Age', and 'Technological Capability'.

Reviewing Communication and Support Services Offered

When selecting a partner for your circuit board manufacturing needs, the importance of effective communication and robust support services cannot be overstated. According to a recent survey from IPC, over 80% of companies cited communication as the top determinant of a successful partnership. A partner who prioritizes clear and regular communication can help preempt manufacturing challenges and rapidly address any discrepancies that may arise during production. Look for partners that utilize modern communication tools, offering instant updates and quick responses to inquiries.

In addition to communication, support services are vital in ensuring seamless collaboration. A report from MBD (Manufacturing and Business Development) indicated that companies offering comprehensive post-manufacturing support experienced a 30% higher customer retention rate. This includes timely technical assistance, warranty services, and a commitment to continuous improvement. By partnering with a manufacturer that provides these vital services, businesses can not only reduce downtime but also foster a long-term relationship that enhances innovation and product quality.

Considering Pricing, Lead Times, and Flexibility in Production

When selecting a partner for your circuit board manufacturing needs, three key factors must be considered: pricing, lead times, and flexibility in production. Pricing remains a critical aspect since it directly affects your overall project budget. It’s essential to evaluate not just the cost per unit but also any hidden fees that may surface during the manufacturing process. A transparent pricing structure can save you from unpleasant surprises, ensuring that you can allocate resources effectively without sacrificing quality.

Equally important are the lead times and flexibility in production. In today’s fast-paced market, having a responsive manufacturer can be a game-changer. Quick turnaround times mean you can expedite your time to market, which is vital for staying competitive. Additionally, flexibility in production allows you to adjust your order sizes, whether you need a small batch for prototyping or a larger volume for mass production. When your manufacturing partner can adapt to your changing needs, you gain a valuable ally in navigating the product lifecycle, from development through to delivery.

Related Posts

-

Top 10 Circuit Board Fabrication Manufacturers from China at the 137th Canton Fair

-

Mastering the Art of Best Printed Circuit Board Assembly Step by Step Guide

-

What is the Importance of Best Circuit Board Assembly in Modern Electronics Industry

-

Solutions for Exceptional Circuit Board Fabrication Techniques

-

Discover Pcb Circuit Board Innovations at the Record Breaking 137th Canton Fair in Guangzhou

-

Solutions for Achieving the Best Printed Circuit Board Assembly Quality in High-Demand Industries

Phone

WhatsApp

WhatsAppEmail

Offer Electronics Manufacturing All-in-One

PCBONLINE® is a registered trademark or service mark of pcb online limited or its affiliates.

Copyright © 2001-2024 Pcb Online Limited. All rights reserved